Manufacturing industries have relied on metal for many years. However, metals can sometimes be problematic. They tend to warp with extreme heat, suffer from corrosion in some environments, and they conduct electricity. This is where ceramic CNC machining comes in. It fills the gap of being able to design and create highly complex pieces with extreme durability.

This machining technology brings design concepts within reach. How does ceramic machining work? What materials can it be used for? And why is it rapidly being adopted in all types of high tech manufacturing? In this post, we’ll answer these questions and help you decide if ceramic CNC machining is suitable for your next high-performance project.

What is Ceramic CNC Machining?

This technology refers to the CNC (Computer Numerical Control) machining of sintered ceramic materials. It is the only machining technology where removal of materials for the purpose of design is accomplished only through brittle fracture, and subsequent grinding. This is otherwise very different from metals (aluminum or steel) where the removal of materials can be soft (and plastic) deformation.

The primary difference between machining metals and machining ceramics lies in the nature of the materials involved. Metals are ductile, transitioning through a variety of states as they’re machined. Ceramics, on the other hand, are brittle and will break if the machining process isn’t properly executed. As such, the machining process needs to be very careful and precise to avoid ruining the piece being worked on.

How Does the Ceramic Machining Process Work?

Because of the nature of ceramics, the machining process has to be somewhat modified from the ceramics machining process. CNC machining has to be adapted from metals to ceramics, and the process at every stage needs to be carefully executed, especially when it comes to the brittleness of the target material, as well as the shape of the piece being machined.

CAD/CAM Design

In CAD, computer-aided design, the process starts. A 3D design of the part to be produced using the desired machining process is built. Ceramics, in particular, requires careful design features, as a design that has sharp internal angles, for example, will act as a stress concentrator and may cause the work to break. Following the design, CNC software that is used in computer-aided manufacting (CAM) to prepare the output in the G-code used to move the CNC.

Specialized Workholding

One of the most challenging parts of the process is securing the workpiece. In metal machining, for example, you can clamp a steel block in a heavy vise. But if you are dealing with a ceramic block, it will likely crack before the cutter even touches it.

For ceramics, machinists work with specially designed workholding, such as:

- Vacuum fixtures: Air pressure systems designed to hold flat parts mildly.

- Soft jaws: Custom-designed clamps that evenly distribute pressure across the part.

- Wax or thermoplastic holding: bonding the part to a plate with a low-melt adhesive.

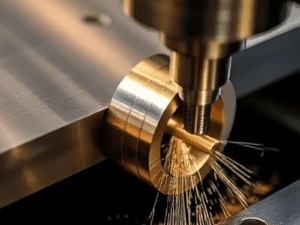

Tooling Considerations

One cannot cut a material with something softer than it. As technical ceramics are harder than even the most hardened steel as well as carbide, standard cutting tools will not do. Ceramic CNC machining is almost exclusively done with diamond-coated tools or CBN Cutters. These tools are some of the hardest materials on earth, and can abrade ceramic materials without dulling instantly.

Coolant and Lubrication

Heat is one of the primary causes of thermal shock failure in ceramic components due to the friction generated by the interface between the tool and workpiece. Therefore, continuous and robust fluid delivery systems are necessary. Flood cooling is the primary means of dissipating heat. It also aids in removing the abrasive ceramic dust (slurry) that can clog tools and damage the machine by overheating due to slow movement dust scrapers.

Types of Ceramics for CNC Machining

There are many types of ceramics with varying characteristics, and they can greatly alter the machining strategy and performance of the final part. Here’s a breakdown of some of the most commonly used ceramics in CNC manufacturing.

Alumina (Aluminum Oxide)

Alumina is one of the most used technical ceramics, balancing properties such as high hardness, great electrical insulation, and chemical resistance. This, combined with its cost-effectiveness, means that it is commonly used for electrical insulators, durable wear liners, and components in semiconductors.

Zirconia (Zirconium Dioxide)

If needed, toughness distinguishes Zirconia. Out of all the technical ceramics, it has the highest fracture toughness, which means Zirconia is the most crack-resistant. Additionally, its thermal expansion is similar to that of steel, allowing Zirconia to fit seamlessly in with metal assemblies. This material is common in the medical field for its durability.

Silicon Carbide (SiC)

The defining property of Silicon Carbide is that, unlike most such materials, it maintains its strength when exposed to extreme heat and is capable of extreme hardness in its own right. The strength of silicon carbide is ideal for the aerospace industry with its need for extreme high-temperture and resilient Seals. high-temperture bearings.

Silicon Nitride (Si3N4)

As silicon nitride is exceptionally strong, it is lighter than steel. In addition to that, it has the ability to resist extreme thermal shock which makes it especially good for rapid heating/cooling systems. This material is especially good in the automobile industry along with systems for moving and working with molten metals.

Macor (Machinable Glass Ceramic)

Macor is one of a kind in the ceramic family. Unlike the materials listed above that require diamond tooling and specialized grinding, Macor can be machined with regular high-speed steel tooling and carbide tools. This is a fast prototyping machinable glass ceramic that allows complex geometries to be created without the high cost of diamond grinding, though it lacks the extreme high wear resistance of the Alumina or Zirconia materials.

Key Techniques in Ceramic CNC Machining

To be able to achieve precision with the machining of ceramics, one must select the right machining operation. Below are the main techniques of doing so in the sector.

CNC Grinding

Sintered ceramics are typically finished with grinding, the most common method. Material is slowly removed with a rotating wheel that is covered in diamond grit. This process is capable of holding extremely tight tolerances (within microns) and achieving a surface finish that is mirror-like. It is most commonly used with flat surfaces or cylindrical forms.

CNC Milling

In the event that a part requires complex 3D contours, pockets, or slots, the process required is CNC Milling which incorporates the use of diamond-impregnated end mills. the strategy usually involves high rotational speeds (RPM) with low feed rates to gently nibble material away instead of taking deep cuts.

CNC Drilling

There is a danger in drilling holes in ceramic. Using a standard drill bit can cause the material to breakout or shatter during the drilling process. In ceramic CNC drilling, broken \”pecking cycles\”—where the drill bit enters the material, retract, and return to enter the material—slow down the contact. In the case of drilling bigger holes, core drilling (removing only the outline of the material to be removed) is better than trying to remove all the material in the middle.

Ultrasonic Machining

This is the latest method that is changing the world of manufacturing ceramics. An ultrasonic spindle that \”vibrates\” the cutting tool at high frequencies (rounded 20,000 times in a second) while the spindle is rotating. This high-frequency cutting increases the ability to fracture the ceramics, decreasing the required amount of force. In the end, the cutting rate is faster while the tool is undergoing less wear and the edge of the ceramic is less likely to chip.

Advantages of Ceramic CNC Machining

Why would anyone go through all the trouble of machining such a complicated material? The answer is simple. Exceptional properties.

Extreme Hardness & Wear Resistance

Ceramic parts in abrasive environments is a better option than the metal. For Industrial machines that works with sand, slurry, or raw minerals, using ceramic parts instead of steel can extend the service of the machine by more than ten times and less maintenance downtime.

High-Temperature Stability

In the case of jet engines or high-velocity manufacturing, the temperatures are extreme. Metals usually soften or creep at high temperatures. However, certain ceramics (Silicon Carbide, Silicon Nitride) do not soften at temperatures greater than 1000°C and remain strong and rigid.

Chemical Inertness

Ceramics are stable and do not rust and rarely react with strong acids and/or alkalis. This property is why ceramic machining is so critical in the chemical processing industry as well as the medical industry where materials are needed to remain pure and are not reactive with biological fluids or harsh cleaning solutions.

Electrical Insulation

After machining, ceramics can be used in electronics and high-voltage applications where strong structural support is needed and electrical conductivity is not allowed. They are excellent electrical insulators and can act as a heat sink, which is an important property for certain electronic applications such as semiconductor housing and circuit substrates.

Challenges in Ceramic CNC Machining

Even with the many advantages, the many distinctive challenges related to ceramic manufacturing present a high barrier to entry.

Brittleness

Ceramics lack ductility, which is their “Achilles heel.” If a tool is pressing too hard, or if a fixture is tightened too much, the piece will shatter. Within this field, there is no scope for mistake – if a crack forms, the piece is usually destined for the scrap heap.

Tool Wear and Cost

Diamond tooling is pricey, and for ceramics, it is worse since they are more abrasive than when cutting aluminum and steel. This rapid tool wear adds to the cost of the part due to high tool wear expenses.

Longer machining times

You cannot rush ceramincs. In order to avoid thermal shock and surface damage, feed rates must be kept slow. if a part takes around 10 minutes to machine out of aluminum, it can take hours when machining out of sintered ceramic.

Cost

Given the costs of the raw materials, the specialized equipment, and the longer machining times, CNC ceramic parts are generally more expensive than their metal counterparts. However, this cost is often recuperated due to the part’s longer operational life and performance benefits.

Applications of Ceramic CNC Machining

The unique properties of technical ceramics have made them indispensable in several high-tech sectors.

- Aerospace:Components must withstand extreme heat and pressure. Ceramics are used for turbine blades, heat shields, and specialized sensors that monitor engine performance.

- Medical:Bio-compatibility is key. Zirconia is widely used for hip and knee replacements because it doesn’t degrade in the body. Ceramics are also used for surgical tools and aesthetic dental prosthetics.

- Electronics:As devices get smaller and more powerful, heat management is crucial. Ceramic heat sinks and insulators are used to protect sensitive microchips and in the manufacturing equipment that produces semiconductors (wafer handling).

- Automotive:High-performance vehicles utilize ceramic composite brake discs for superior stopping power and heat dissipation. Ceramics are also found in various engine sensors and components to improve fuel efficiency.

Choosing the Right Path for Your Project

When it comes to applications where standard materials cannot compete, ceramic CNC machining delivers unparalleled performance, durability, and precision. There are also challenges to the process, such as expense, brittleness, and longer lead times. When completed, the end product is a component that can survive the most extreme conditions on the planet.

For those who are willing to take the risks to surpass the benchmarks set for product performance, ceramics can be the answer to your search. In order to facilitate your efforts in overcoming the challenges associated with ceramics, please get in touch with our team, and we will provide you with a quote and work with you to design your next project to maximize the results that can be achieved.

Frequently Asked Questions (FAQ)

Q: Is ceramic harder to machine than steel?

A: Absolutely, yes. Steel, although hard, is ductile, which makes it cutting behavior somewhat predictable. In contrast, ceramics are brittle and abrasive. Consequently, when we grind the ceramic material, we need to use slower speeds and highly specialized diamond tooling to fracture the material in a controlled manner to avoid shattering.

Q: Can you use standard CNC machines for ceramics?

A: The answer is yes, but with risks. Machining ceramics, when done dry, creates a fine and abrasive dust. When it is done wet, a slurry is produced which can be even more damaging to your standard CNC machine. Because of this, ceramic machining CNCs are equipped with improved dust control and containment systems.

Q: What type of ceramic can be shaped the easiest?

A: The easiest to machine include Macor (Machinable Glass Ceramic) and Boron Nitride. They can be shaped using regular high-speed steel and carbide tools, which mean they won’t need to go through diamond grinding, which is useful when dealing with prototypes.

Q: Why is the machining of ceramics so costly?

A:Three key components drive the price: the high price of the raw ceramic material, the slow cycle times required to safely machine the part, and the quick wearing of diamond-coated tooling at great expense.