Among the first materials ever utilized in manufacturing, the bronze alloy has been utilized and trusted by engineers since antiquity. Bronze is machined in many fields, including aerospace and marine, due to its impressive durability and corrosion resistance, as well as having low friction characteristics.

This guide intends to cover the gamut of CNC machining bronze, from the various alloys of bronze and how to select the best as per your needs, to the various intricacies associated with the machining of bronze.

What is Bronze Machining?

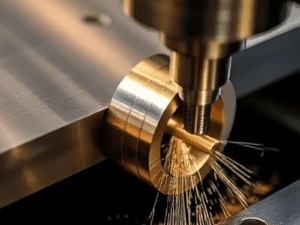

In a nutshell, machining bronze is a type of subtractive manufacture where, with the use of CAD/CAM software and CNC machining, a bronze alloy is transformed from a solid block into the desired shape. Bronze can be melted and cast into a pre-determined shape, however, for many high-performance applications, it is preferable to machine the alloy as this will result in much better control of tolerances, as well as a smoother surface finish.

The most common alloy with bronze is copper, with the main alloying metal being tin, however to fine-tune the desired alloy characteristics one can also use other metals such as zinc, manganese, aluminium, or nickel.

One of the reasons why this substance is used includes the machining behavior of the material. In general, the different varieties of bronze alloys present good ratings in machinability, although it is contigent on the specific variety. In addition to ease of cutting, other valuable properties of the material include high thermal conductivity and excellent resistance to friction which makes it ideal for components that slide against other metals too, such as gears and bushings.

The CNC Bronze Machining Process

Although bronze has been manually worked for centuries, it has reached an entirely new level of precision and repeatability with copper bronze CNC machining. Computer Numerical Control (CNC) systems make it possible to execute complex shapes that hand machining cannot achieve.

CNC Turning vs. CNC Milling

The particular CNC method employed is based on the geometry of the part to be manufactured.

- CNC Turning: If the parts are cylindrical, such as bushings, bearings, or shafts, then it is the most common method. A CNC lathe is the preferred tool. The bronze workpiece rotates while in it, a fixed cutting tool removes the material.

- CNC Milling: If the workpiece is not cylindrical, such as with brackets, plates, or intricate housings, then it is not an exception. The workpiece is still stationary while in it, a rotating cutting tool moves across the surface to carve the specified shape.

Choosing the Correct CNC Bronze Machining Tool

CNC machining bronze is based heavily on the tool. They are preferred to be carbide because of the higher temperature along with both higher cutting speed and lower cutting speed. This results in a snippet of longer tool life and better surface finish.

It is important to find the “sweet spot” for cutting speeds since bronze is tougher than plastic but softer than steel. If cutting speeds are too slow, the tool can rub and cut, resulting in work hardening. However, if cutting speeds are too fast, heat generation can compromise the final tool’s dimensional accuracy.

Bronze Alloys Grade for CNC Machining

The common misnomer of referring tobronze singularly as if it is one distinct material is misplaced. In point of fact, it is a category of alloys, and as a result, the most important decision to make in the fabrication process is the selection of the appropriate grade. Each grade presents a different combination of sculptability, tensile strength, and resistance to rust.

C932 Bearing Bronze (SAE 660)

C932, also known as SAE 660, is perhaps the most widely used bronze alloy in the machining world. Its composition includes copper, tin, and lead.

- Properties:The lead blended in this alloy gives it high machinability as well as self-lubrication tendencies. The bronze is not heat-treatable, rather it is tougher and offers high resistance to the wearing.

- Best Use:As the name suggests, this is the gold standard for bushings, bearings, and thrust washers where low friction is required.

C954 Aluminum Bronze

C954 Aluminum bronze is among the most favorable bronze to utilize whenever strength is required as it is a high strength alloy of Aluminum, Iron and nickel.

- Properties: It presents a greater yield strength and high resistance to rust including wearing and fatigue as it is mechanical in nature even at high temperatures unlike C932.

- Best Use:It is suitable for heavy-duty loads and high-stress environments, such as heavy equipment bearings, valve guides, and aircraft landing gear components.

C260 Cartridge Brass (Brass-Bronze Alloy)

While technically a brass (copper and zinc), C260 is often grouped with bronze in machining contexts due to similar applications and processing.

- Properties:Known for having the highest ductility of the yellow brasses, it has excellent cold workability. It is highly resistant to corrosion but is generally harder to machine than leaded bronzes.

- Best Use:It is frequently used in ammunition components (hence the name), fasteners, and hardware where deep drawing or forming is required.

C510 Phosphor Bronze

C510 is a grade defined by the addition of phosphorus to the copper-tin mix.

- Properties:The phosphorus increases the wear resistance and stiffness of the alloy while refining the grain structure. It is known for its excellent fatigue resistance and elasticity.

- Best Use:Because of its spring-like qualities and electrical conductivity, it is ideal for electrical connectors, switch parts, and spring washers.

Applications of Machined Bronze Parts

The versatility of machining bronze means it is found in almost every sector of the industrial economy.

Marine Industry

Most metals corrode in contact with salty water, but bronze is naturally resistant.

- Key Parts:Ship propellers, underwater fittings, pumps, and valves.

- Why:Bronze forms a protective oxide layer that prevents deep corrosion, ensuring longevity even when submerged.

Automotive & Aerospace

In these industries, failure is not an option, and parts are often subjected to high friction and heat.

- Key Parts:Transmission pilot bushings, valve guides, landing gear components, and connecting rod bearings.

- Why:The low metal-to-metal friction of bronze prevents seizing and reduces wear on mating steel parts.

Industrial Equipment

Heavy machinery requires components that can take a beating and keep running.

- Key Parts:Worm gears, wear plates, and hydraulic components.

- Why:Bronze gears are often paired with steel worms; the bronze is sacrificial, meaning it will wear down slowly before the more expensive steel shaft does, protecting the overall system.

Electrical

Conductivity combined with durability makes specific bronze alloys essential for electronics.

- Key Parts:Circuit breaker terminals, fuse clips, and spring connectors.

- Why:Phosphor bronze (C510) provides the electrical path while maintaining the spring tension needed to keep a tight connection.

Common Challenges in Bronze Machining

Although bronze is considered one of the most machinist-friendly materials, there are some concerns with it. Specific behaviors with the alloy can lead to the ruining of a workpiece or the damaging of the tooling if the operator is not aware of them.

Work Hardening

This is arguably the biggest challenge when working with copper-based alloys. The cutting tool will remain stationary or the feed rates will be too slow, causing the pressure to compress the material instead of cutting it. The surface also hardens, preventing cutting material. This is known as work hardening.

The Fix: Make sure to maintain a steady, aggressive feed rate with sharp cutting tools. The alloy surface should never be rubbed by the tool.

Chip Control

Lead Bronze allots (C932): This alloy produce a set of short, brittle chips that are easily managed.

Aluminum Bronze (C954): This alloy can produce some long and stringy chips that bird nest, meaning they wrap around the tool or part and can cause surface damage or tool breakage.

The Fix: Employ high pressure coolant to rapidly remove chips.

Surface Finish

Bronze does have the advantage of achieving a nice, gold-like finish, but it scratches and is soft enough to be damaged easily. Also, the machining of this material causes thermal expansion, which can cause problems with tolerances.

The Fix: Finishing should be done with a separate pass using a higher spindle speed and a reduction in feed rate. It is also important that the component is kept cool to avoid issues with dimensional stability.

Safety Considerations When Machining Bronze

Safety is paramount in any machine shop, but machining bronze introduces specific hazards that must be managed.

Dust and Fumes

The primary concern is the inhalation of fine metallic dust. While copper dust is an irritant, the additives in bronze are the real danger.

- Lead:Many machining bronzes (like C932) contain lead. Inhaling or ingesting lead particles can lead to serious long-term health issues.

- Beryllium:Though less common, Beryllium Copper is highly toxic, and machining it requires strict hazardous material protocols.

PPE (Personal Protective Equipment)

Operators should always wear standard machine shop PPE, including safety glasses and steel-toed boots. However, when working with dry bronze (without flood coolant), wearing a properly fitted respirator rated for metal fumes/dust is highly recommended.

Ventilation

General shop HVAC is often insufficient. Localized exhaust ventilation (LEV) systems should be placed near the CNC machine to capture dust and mist at the source. If using flood coolant, ensure the filtration system is designed to handle fine bronze particles to prevent pump wear.

Conclusion

Bronze alloy CNC machining gives us properties that we cannot get with plastics and steel. This material is paramount for producing long-lasting, low-friction, and corrosion-resistant products; from ocean deep to the aircraft’s engines.

The first step is selecting the correct alloy. The toughest load is C954 and for bearings; that is the standard C932. The second steps is knowing how to machine it.

Ensure the right expertise is right by your side when starting your next project. You can get in touch with bronze machining experts and engineers to choose the right alloy with the best pricing from Bonbby.

Frequently Asked Questions (FAQs)

Q: Is bronze easy to machine?

A: On the whole, yes. Most standard bronze alloys, and especially those that contain leads, such as C932, have machinability ratings of 100 percent (as per the guidelines of free cutting brass). They contribute small shave-offs of material and result in minimal wear on the tool. With that said, alloys that have high strength, such as aluminum bronze, are more difficult, and more abrasive, needing more robust tools that must spin at slower rates.

Q: What is the difference between brass and bronze machining?

A:Despite the fact that they are both copper alloys, brass (copper and zinc) is generally more feasible to machine than bronze (copper and tin). Brass is more suitable for cosmetic and low-friction uses, while bronze is more appropriate in environments and applications that require a high degree of structural strength, wear resistance, and corrosion resistance.

Q: Can you machine bronze dry?

A: It is possible, but not recommended for high-precision or high-speed operations. Using coolant helps flush away chips, prevents the workpiece from overheating (which affects tolerance), and lubricates the cutting action to improve surface finish. Dry machining increases the risk of work hardening.

Q: Why does my bronze part deform after machining?

A:This is usually due to internal stresses in the material or clamping pressure. Because bronze is softer than steel, clamping it too tightly in a vice or chuck can deform it. Additionally, removing a large amount of material can release internal stresses, causing the part to warp. Stress-relieving the material before machining can help.

Q:What is the best coolant for machining bronze?

A:Water-soluble oils are typically the best choice. They provide excellent cooling properties to manage heat generation and offer sufficient lubrication to prevent the material from sticking to the tool (built-up edge). Avoid coolants with active sulfur, as they can stain the bronze workpiece.