High-density polyethylene (HDPE) is an engineered thermoplastic with a remarkable strength-to-weight ratio, chemical resistance, and long-term durability. It is widely used in the packaging industry, and parts such as construction, automotive, and electrical components can be manufactured from CNC machined HDPE.

This article discusses the properties of HDPE, the process of CNC HDPE, and its various applications.

What is HDPE?

HDPE is a thermoplastic polymer with a density ranging from 0.93-0.97 g/cm³, making it lightweight and robust. This combination is essential for applications requiring flexible structural integrity.

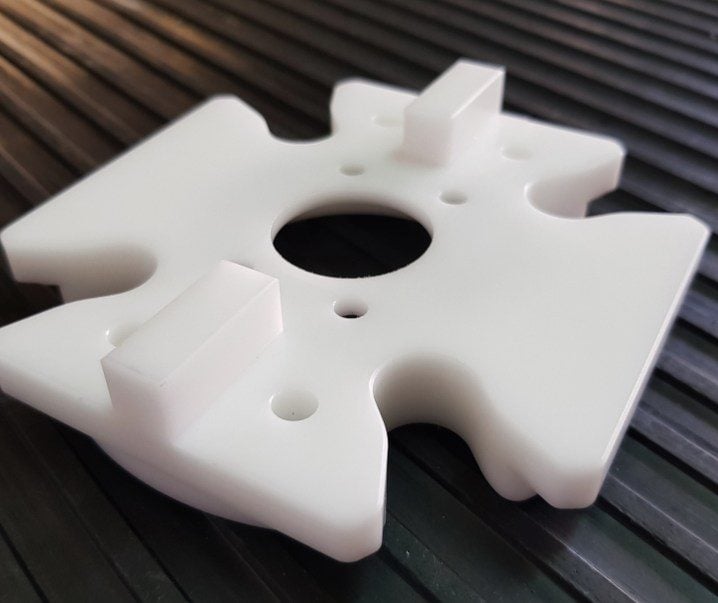

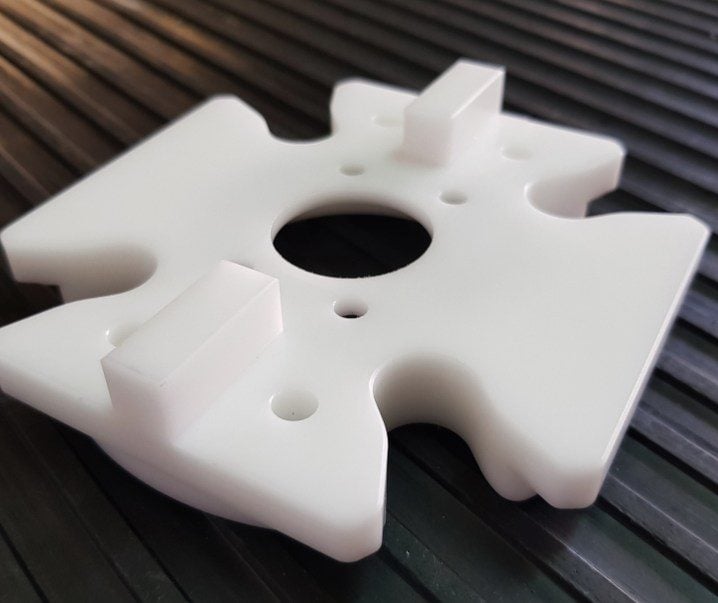

HDPE is a polymer with advantageous characteristics, one of them being a strength for portion control. CNC machining is a process that needs precision, and it works well with HDPE. CNC machining augments the capabilities of HDPE by transforming virgin HDPE blocks into formed HDPE parts using milling, turning, and drilling.

The Properties of HDPE

Exceptional Chemical Resistance

Among the various types of thermoplastics, HDPE is more resilient and can withstand exposure to harsh chemicals like acids, alkalis, and solvents. Unlike metals that corrode or plastics that degrade, CNC machined HDPE parts excel in aggressive environments. This property makes HDPE ideal for laboratory equipment, chemical storage tanks, and industrial piping.

Impact Strength

Holes, defects, and cracks on the surface do not appear under high impact stresses, and HDPE is capable of absorbing shocks extremely well. This ability to withstand internal and external impacts not only makes it easy to use but also makes it very durable in construction, marine, automotive, and other parts where HDPE machined components are required.

Low Weight

Compared with metals like steel and aluminium, HDPE is ultra-light with a density of 0.93-0.97 g/cm³ due to its low structural weight. Its low density reduces transportation expenses, which is beneficial to construction sectors along with simplifying handling in aerospace and packaging industries. Even with a reduced HDPE plastic, its structural strength remains exceptional.

Eco-friendly and Fully Recyclable

The trend towards eco-friendly manufacturing can be supported by the fact that HDPE is fully recyclable. Components made out of reused rHDPE can be machined, and the characteristics retained, which is critical for sustainable fabrication as well as ensuring performance for food-grade and consumer products with stringent requirements for post-processing safety and reliability.

Types of HDPE for CNC Machining

Standard HDPE

Standard HDPE is the most prevalent type because it provides a good balance between cost, chemical resistance, and ease of machining. It works best for HDPE fabricated general-purpose goods such as containers, pipes, and electronic component parts. General-purpose machined HDPE has a competitive price which, along with welded HDPE, makes it easy to prototype and use in low-cost production.

UV-Stabilised HDPE

This kind is augmented with UV-blocking additives and is resistant to sunlight. It prevents brittleness and colour fading over time. It is ideal for outdoor applications like marine fittings, playground equipment, and agricultural components that endure harsh weather.

Cross-Linked HDPE (PEX)

PEX is created by a chemical process that strengthens its molecular bonds, increasing its resistance to heat and chemicals. It is best suited for hot-sampling machining of HDPE, for instance, hot water pipes, underfloor heaters, and industrial fluids.

Ultra-High Molecular Weight HDPE (UHMWPE)

UHMWPE is well-known for its outstanding wear resistance as it can withstand heavy abrasion. It is typically used to make gears, bearings, and conveyor components. It can be more difficult to machine, but it is unrivalled in energy-intensive conditions like mining or food processing.

CNC Machining HDPE Processes

CNC Milling

CNC milling is the preferred technique for making complex HDPE machined parts with complicated features. During CNC milling, the solid block of HDPE is carved to the appropriate shape with rotating cutting tools, also known as CNC mills. Each prototype or low volume production run is done with care to avoid excessive heating of the HDPE. The operators use sharp carbide tools, which combined with moderate spindle speeds of 400–1,000 RPM, deliver smooth edges and precise dimensions.

CNC Turning

Particularly for cylindrical parts like pipes and bushings, CNC turning is highly efficient. The HDPE workpiece spins with the rotating spindle. A stationary tool does work which consumes material. The precision of rounding is congruent to the balance of the workpiece and tool’s rotation; it is congruent to the tolerances of 0.05 mm. This method has faster processing speeds than milling for symmetrical parts; however, it is less versatile when it comes to complex designs.

CNC Drilling

The process of forming clean holes or accurate holes within HDPE sheets or blocks is streamlined through CNC drilling. The structure of the material also depends on a specialised drill bit used. This drill head utilises minimal friction and heat. This process is often combined with other procedures like milling or turning to make additional functional features such as fluid channels or mounting holes.

CNC Routing

In the case of cutting large sheets of HDPE, CNC routing is best for cutting 2D shapes or patterns. Routers spin at an increased rate which is beneficial when cutting large amounts of flat parts such as panels or signs. From a cost-effective perspective, this makes routers better suited for signage. However, they are not as good as milling for 3D contours.

Comparison between CNC Machining, injection moulding and 3D printing

Precision Comparison

- CNC machining achieves tighter tolerances of ±0.025 mm with computer-operated cutting tools, ideal for aerospace or medical parts.

- Injection moulding precision stands at ±0.1 mm but is limited by the mould’s quality and shrinkage of the material.

- The consistency of layers, which is still a work-in-progress, is a challenge for 3D printing. FDM printers average ±0.2 mm; however, resin-based SLA/DLP surpass it at ±0.05 mm.

Surface Finish Quality

• Surfaces of CNC milled components are smooth (Ra 0.8–3.2 μm) and require very little polishing, if any at all.

• The surfaces of injection-moulded parts replicate the surfaces of the mould, Ra 0.4–1.6 μm; however, they may also have flow marks.

• Parts that have undergone 3D printing have layer lines that are visible to the naked eye (Ra 5–15 μm for FDM) and require sanding or chemical smoothing.

Production Speed & Scalability

• CNC machining has great flexibility with low-volume batches, taking hours per part.

• Injection moulding offers mass production at a high speed (taking seconds per part after mould setup), although it comes with costly initial expenses.

• 3D printing offers the best speed for prototyping (with no tooling required) but slows down significantly for orders that are not small-scale.

Industry Applications of CNC-Machined HDPE

Medical & Pharmaceutical Devices

Medical-grade HDPE components, such as handles for surgical instruments, IV fluid bottles, and drug packaging, benefit from HDPE’s non-toxic, chemical-resistant characteristics. Its polished surface inhibits bacterial growth, complying with rigorous FDA standards for OR and laboratory cleanliness.

Chemical Industry

CNC machined HDPE components, from acid storage tanks to valves resistant to solvents, are able to withstand corrosive liquids without damage. Their weldability makes them ideal for use in leak-proof seals within pipelines and reaction vessels containing acids, alkalis, and industrial solvents.

Construction & Infrastructure

Moisture resistance and durability of HDPE is showcased in construction areas like waterproof insulation panels and underground piping systems, as well as lightweight scaffolding components. UV-stabilised types are utilised for outdoor fixtures subjected to rain and temperature changes.

Marine Engineering

Saltwater-resistant HDPE marine parts such as boat hatch covers, dock fenders, and buoyancy aids are well protected from corrosion and UV damage. Critical parts like propeller bushing and seawater intake fitting are handled with CNC to guarantee accurate fits.

Food-Safe Containers

Food trays, beverage bottles, and multiuse storage containers are produced from plastic grade HDPE. A non-reactive surface, CNC engineered airtight stoppers and liquid dispensers with tight seals, “non-flavouring” surfaces, and soldered CNC surfaces make them airtight.

Automotive Innovations

Fuel tanks and coolant reservoirs made from HDPE help cut down the weight of the vehicles which increases fuel efficiency. Interior parts and dash panel also undergo CNC to reduce vibrations and improve the passenger experience.

Child-Safe Toys

Slides from playgrounds, bricks used as toys and tools for sandpits, and other tools are designed for use outdoors. The impact resistance and non-toxicity of HDPE make it excellent for use. Edges are rounded through the application of CNC to ensure compliance with international standards for children’s safety.

Conclusion

Precision, reliability, and sustainable features enhance the capability of industries needing specific high-performance aspects of plastics when HDPE is CNC machined. Marine parts that resist corrosion, such as food containers that need FDA approval, show that HDPE machined parts work in extreme conditions while optimally reducing costs and environmental waste.

Prepared to take your next venture to the next level? Get in touch with us today for a bespoke estimate or to discover how HDPE can tackle and solve your most challenging engineering problems.

Frequently Asked Questions (FAQs)

Q: Can CNC machining handle recycled HDPE materials?

A: Yes, recycled HDPE (rHDPE) can be machined with CNC processes, retaining similar strength and chemical resistance. However, impurities in recycled stock may require adjusted tooling speeds for optimal results.

Q: What surface finishes are possible for HDPE machined parts?

A: CNC machining HDPE achieves smooth finishes naturally. Additional options like polishing or anti-static coatings can enhance aesthetics and functionality for medical or electronic applications.

Q: Is HDPE suitable for high-temperature environments?

A: Standard HDPE withstands temperatures up to 120°C (248°F). For extreme heat, cross-linked HDPE (PEX) or UHMWPE variants offer better thermal stability up to 150°C (302°F).

Q: How does HDPE compare to PVC in CNC machining?

A: HDPE is lighter, more impact-resistant, and recyclable, while PVC offers higher rigidity. CNC machining HDPE generates less toxic fumes, making it safer for workshops.

Q: Can HDPE parts be welded after CNC machining?

A: Yes, HDPE’s thermoplastic properties allow hot-air or ultrasonic welding to assemble machined components, ideal for creating leak-proof seals in tanks or pipelines.