The CNC Machining materials you choose dictates not only the functionality and durability of the final part but also the cost, production time, and machining technique required.

There are many different kinds of metals and plastics to choose from. Do you want the lightweight strength of aluminum, or do you want the corrosion resistace of stainless steel? Do you need a high-performance plastic like PEEK, or is ABS an acceptalbe choice?

This guide examines the most frequently CNC machined materials, discusses the ways in which their characteristics affect the machining, and presents anic practical suggestions to help you refine your choices to achieve the best performance for the lowest possible cost.

Commonly Used Materials for CNC Machining

The types of materials that can be used in the machining process are of almost every conceivable type, but in the industry primarily, metals and plastics are most used.

Metal Materials Used for CNC Machining

Metals used in CNC Machining are the most common because of their strength, durability, and thermal resistance.

- Aluminum:This metal is, without exaggeration, the most commonly CNC machined metal. In comparison to other metals, it is lightweight, can be machined easily, and has good strength-to-weight ratios. 6061 is a common versatile alloy and 7075 is a higher strength alloy used in the aerospace industry. Due to its corrosion resistance, it is used in parts for the automotive, aerospace, and even consumer electronics industries.

- Stainless Steel:This metal is known for its strength, and resistance to corrosion and rust. Because of these reasons, it is heavily used in the medical, food, and marine industries. 303 is the easier grade to machine, 304 and 316 are the tougher grades and also have more superior corrosion resistance, but they’re tougher on the cutting tools.

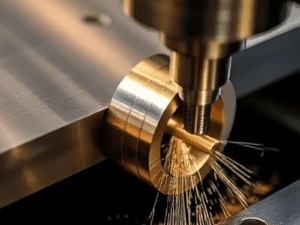

- Brass: This metal is also known to be very easy to machine. It has good electric conductivity, a very nice aesthetic finish, and produces very little friction when machined. Because of these reasons, it is used for valves, electrical nozzles, and some other electrical hardware.

- Titanium: Because of its strength-to-weight ratio, resistance to temperature, and resistance to corrosion, titanium is essential to the field of aerospace and medical implants. However, titanium is difficult to machine and its thermal conductivity is poor. Therefore, titanium wears down tools quickly.

- Steel (Carbon and Alloy): Steel provides the utmost strength and durability. Low carbon steels are typically easier to work with than high carbon steels. Alloy steels such as 4140 are used for more heavy-duty applications and are also heat-treatable. These applications include shafts and gears.

Plastic Materials Used for CNC Machining

For their lightweight and insulating characteristics, as well as their ability to resist corrosive chemical environments, plastic is often a suitable choice of material. They are popular, for example, in medical devices and electronic devices, both during the prototyping phase and in the final production of devices.

- ABS (Acrylonitrile Butadiene Styrene): ABS is one of the most common engineering plastics. It is cheap, easy to machine, and even impact resistant; this is one of the many reasons rapid prototyping is often in the engineering world.

- Nylon (Polyamide): Known for being extremely strong, durable, and wear resistant, it is highly sought after to craft low friction component parts. However, due to the fact that nylon is highly absorbent, moisture that is present in the air can impact the nylon and cause it to warp.

- Delrin (POM): Delrin is perfectly suited for plastic precision engineering applications due to their high dimensional stability and low friction. It is also a popular substitute material for metal when it comes to engineering parts like fasteners and bushings.

- PEEK (Polyetheretherketone): For very high performance applications that need to resist extreme temperatures, chemically corrosive environments, and very demanding conditions (for example, the medical and aerospace industries) a premium priced plastic known as PEEK is used.

- Polycarbonate (PC): Polycarbonate is also a highly sought after engineering plastic. It is transparent, known for high impact strength, is often used in a wide range of optical applications, and also is used in safety goggles and systems that handle various fluids.

Material Properties and Their Impact on CNC Machining

When CNC Machining, knowing basic material properties will help in predicting how materials will perform under the cutting tool.

Hardness

Hardness indicates how much stress a material can take without deforming.

- Impact: If a material is too hard (i.e. hardened steels, titanium), the cutting speeds will have to be lowered drastically to avoid tool breakage, in turn increasing machining time and costs.

- Selection Tip: Specify a higher hardness level only if the material is to be subjected to a lot of wear or abrasion.

Machinability

Machinability is the easiness to cut a certain material. More often than not, it is a comparative rating where free machining steels (1212) is given a 100% rating.

- Impact: Materials with a high machinability rating (i.e. Aluminum 6061, Brass) get the job done much faster, with less tool wear, and will be cheaper to produce.

- Selection Tip: If your design allows it, always materials with higher ratings to minimise costs.

Thermal Stability

Thermal stability of a material is its reaction to heat.

- Impact: Machining generates frictional heat. If a plastic has low thermal stability, it can melt or warp if machined too aggressively. Poor thermal conductivity metals like titanium will concentrate a lot of heat towards the cutting tool, reducing its life.

- Selection Tip: If machining is to be done aggressively, or if it is a high temp application, materials with high thermal stability should be selected.

Tensile Strength

Tensile Strength refers to the amount of stress a material can withstand while under tension before it breaks.

- Impact: If a material having high tensile strength is chosen for machining, it is likely to make machining more difficult.

- Selection Tip: Ensure the tensile strength is sufficient for the structure, but avoid specifying strength that is more than sufficient if the component is not load bearing.

Cost Implications of Different Machining Materials

The cost of a CNC machined part is rarely just the cost of the raw block of metal. It is a combination of raw material costs, machining time, and tool wear.

The Raw Material Cost

This is the most apparent consideration.

- Low Cost: ABS, Aluminum 6061, Mild Steel.

- Medium Cost: Stainless Steel 304, Nylon, Polycarbonate.

- High Cost: Titanium, PEEK, Stainless Steel 316.

The Hidden Cost: Machinability

This is where budgets often break. A block of Titanium might cost five times more than a block of Aluminum, but the real cost comes from the machine time. Because Titanium must be cut slowly to avoid damaging the equipment, the machine might run for 10 hours for a part that would take 1 hour in Aluminum.

If you are paying an hourly rate for machining, that 10x increase in time dwarfs the raw material cost.

Tool Wear and Replacement

Abrasive materials like glass-filled nylon or hard metals wear down end mills and drill bits quickly. If a machinist has to stop the machine to replace a dull tool halfway through the job, you are paying for that downtime and the cost of the new tooling.

Tips for Optimizing Material Selection for CNC Machining

You can reduce costs and lead times by following these optimization strategies during the design phase.

1.Do Not Over-Specify

Just because Grade 5 Titanium is the “best” material to use for the design doesn’t mean it has to be used. Engineers must use materials that are actually the most cost-effective. If the part is going to sit on a desk, and simply function to hold a sensor, then an expensive version of high-grade steel isn’t needed.

2.Standardise Your Billet Sizes

When machining CNC components, the machinists get their stock materials in bar, rod, and plate sizes. If a design says the part is 51mm wide, the machinist has to get a 60mm bar and mill off 9mm of material. If the part is instead designed to be 49mm wide, then they can use a 50mm bar and no material is wasted. Less time is required for machining.

3.Think About Post-Processing

If a specific surface hardness is needed, and the part has to be easily machined, secondary processes must be put into place. Softer steels can be used in case-hardening, and the same is true for Aluminum which can be used and anodized for a surface layer that is more wear and corrosion resistant.

4.Consider the Thickness of your Walls

While this applies to all other materials, it is even more critical when it comes to plastics. Machining processes can create uneven surface finishes and can, more dangerously, cause cracks in the workpiece if the wall is thinner in design. Oversize your wall thickness and ensure it is enough to endure the impact of the cutting instrument.

Conclusion

Selecting the right material for CNC machining is rarely a black-and-white decision. It is a negotiation between the physical demands of the final product and the economic realities of manufacturing. By understanding the trade-offs between machinability, cost, and mechanical properties, you can design parts that are not only functional but also efficient to produce.

Whether you are leaning towards the versatility of aluminum, the durability of steel, or the precision of Delrin, the key is to involve your manufacturing partner early in the design process. Their on-the-floor experience can provide invaluable insights that save time and money before the first chip is ever cut.

Frequently Asked Questions

Q: What is the cheapest metal for CNC machining?

A: Typically, Aluminum 6061 is the cheapest. While some mild steels have a cheaper raw material price on a per pound basis, Aluminum cuts much faster which lowers the total cost of production.

Q: Can you CNC machine rubber?

A: Very difficult. Rubber is way too soft and flexible. Instead of being cut, it tends to get pushed away from the cutting tool. For rubbery materials, machining a mold and casting the part is better. Using harder elastomers like Polyurethane (PU) with some freezing is also better.

Q: Why is titanium so expensive to machine?

A: Because it low thermal conductivity (it gets hot), and is also chemically reactive with cutting tools (causing attrition of them). Also, it is physically hard to cut so it’ll wear tools out faster. Because of this, machinists have to move slowly and change out cutting tools more often.

Q: What is the best plastic for holding tight tolerances?

A: For tight tolerances, Acetal (Delrin/POM) is the best plastic. Unlike Nylon, it is stiffer, dimensionally steady and moisture absorption resistant.