Titanium metal has become a core material in aerospace, medical implants, high-end manufacturing and other fields due to its high strength, corrosion resistance and biocompatibility. However, untreated titanium surfaces often have microscopic roughness or oxide layers, which directly affect its functionality and life. Through precision titanium polishing technology, the surface roughness (Ra value) can be reduced to below 0.05 microns, forming a mirror-like smooth effect, while significantly improving its wear resistance and fatigue resistance.

In the following chapters, we will deeply analyze the core steps, technical classification and cross-industry applications of titanium polishing, and explore how to choose an efficient and reliable polishing service provider to provide professional solutions for your project.

Basics of titanium polishing

Titanium polishing is a process that optimizes the surface properties of titanium metal by mechanical or chemical methods. Its core goal is to reduce the surface roughness (Ra value) and achieve a mirror effect. Ra value (arithmetic mean roughness) is a key indicator to measure surface smoothness and is usually controlled in the range of 0.1 to 0.05 microns to meet the functional requirements of high-precision parts. For example, medical implants require Ra values below 0.05 microns to reduce the risk of bacterial attachment, while aerospace parts rely on mirror polishing to reduce air resistance and improve high temperature resistance.

Detailed steps for titanium polishing

Step 1: Cleaning and degreasing

The first step in titanium polishing is to thoroughly clean and degrease to ensure that there is no grease, oxide or processing residue on the surface. Neutral cleaners (such as isopropyl alcohol or special metal cleaners) are preferred, and chemical products containing chlorine or bleach are avoided to avoid corrosion or discoloration of the titanium surface. For complex parts or deep stains, ultrasonic cleaning technology can be used – high-frequency vibration waves penetrate microscopic pores and efficiently remove stubborn contaminants. After cleaning, rinse with deionized water and wipe dry with a dust-free cloth to prevent water stains from remaining.

Step 2: Sandpaper polishing

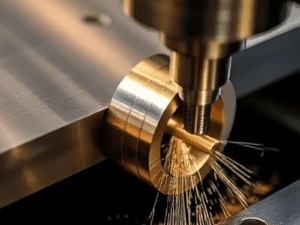

Sandpaper polishing is the core link to reduce surface roughness. Usually start with 200-grit coarse sandpaper and gradually transition to 2000-grit ultra-fine sandpaper to gradually eliminate scratches and bumps. Lubricants (such as deionized water or light mineral oil) are required during operation to reduce friction heat and prevent oxidation of the titanium surface. The polishing direction should be consistent to avoid cross-textures; for curved surfaces or edges, a flexible sandpaper backing can be used to improve fit. During this stage, the pressure must be strictly controlled to ensure uniform material removal and lay a smooth foundation for subsequent polishing.

Step 3: Polishing wheel and polishing agent

When entering the fine polishing stage, the polishing wheel material needs to be selected according to the target gloss. Soft cotton wheels are suitable for initial brightness improvement, while silicone or composite fiber wheels are used for high-precision mirror effects. The polishing agent is mostly made of diamond micropowder or alumina-based paste, and alcohol is used to clean the surface dust. During the polishing process, cooling water or low-viscosity oil needs to be sprayed intermittently to control friction heat and avoid local overheating that causes deformation of the titanium material or thickening of the oxide layer.

Step 4: Final treatment

After polishing, the surface needs to be protected with fluorocarbon resin or silicone-based sealant to enhance corrosion resistance and prolong the gloss durability. For minor defects (such as pinholes or shallow scratches), local manual repair can be used – dip a microfiber cloth in a special polishing paste and gently polish in a circular motion. Finally, the Ra value is tested by a white light interferometer or a surface roughness meter to ensure that it meets the design requirements (usually ≤0.05 µm). The quality control at this stage directly determines the functionality and aesthetic value of the parts.

Grades of titanium polishing

The titanium polishing process is divided into four grades according to the surface accuracy requirements:

- Rough polishing

Use silicon carbide grinding wheel or 80-200 mesh sandpaper to quickly remove machining marks and oxide layers, and the surface roughness (Ra value) is reduced to 1.6-3.2 µm, which is suitable for pre-processing or chamfering of structural edge.

- Medium polishing

Use aluminum oxide sanding belt or 400-800 mesh sandpaper to further smooth the surface, with Ra value of 0.4-0.8 µm, which is commonly used in primary gloss treatment of automotive parts or tool handles.

- Fine polishing

With the help of diamond polishing paste and 1000-2000 mesh sandpaper, the Ra value is controlled at 0.1-0.4 µm, which is used for semi-glossy preparation of medical devices or electronic components.

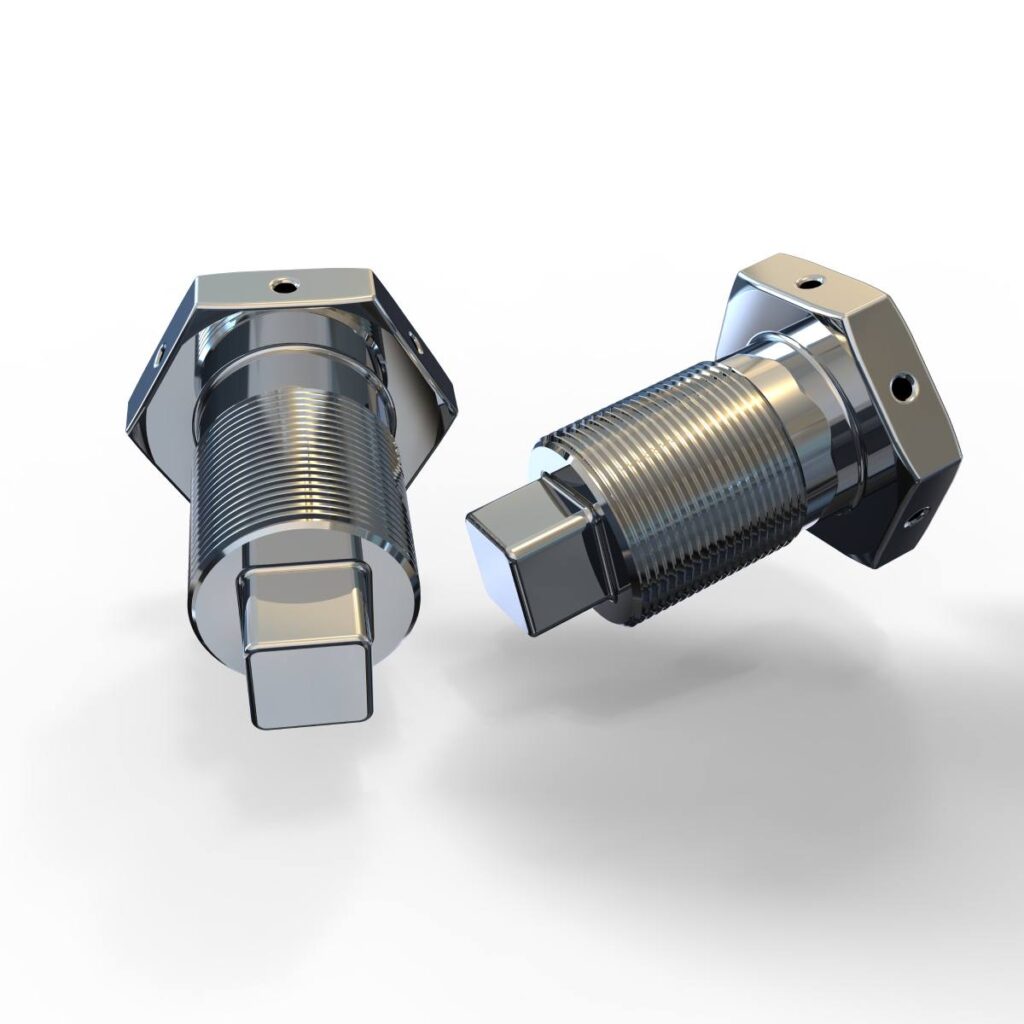

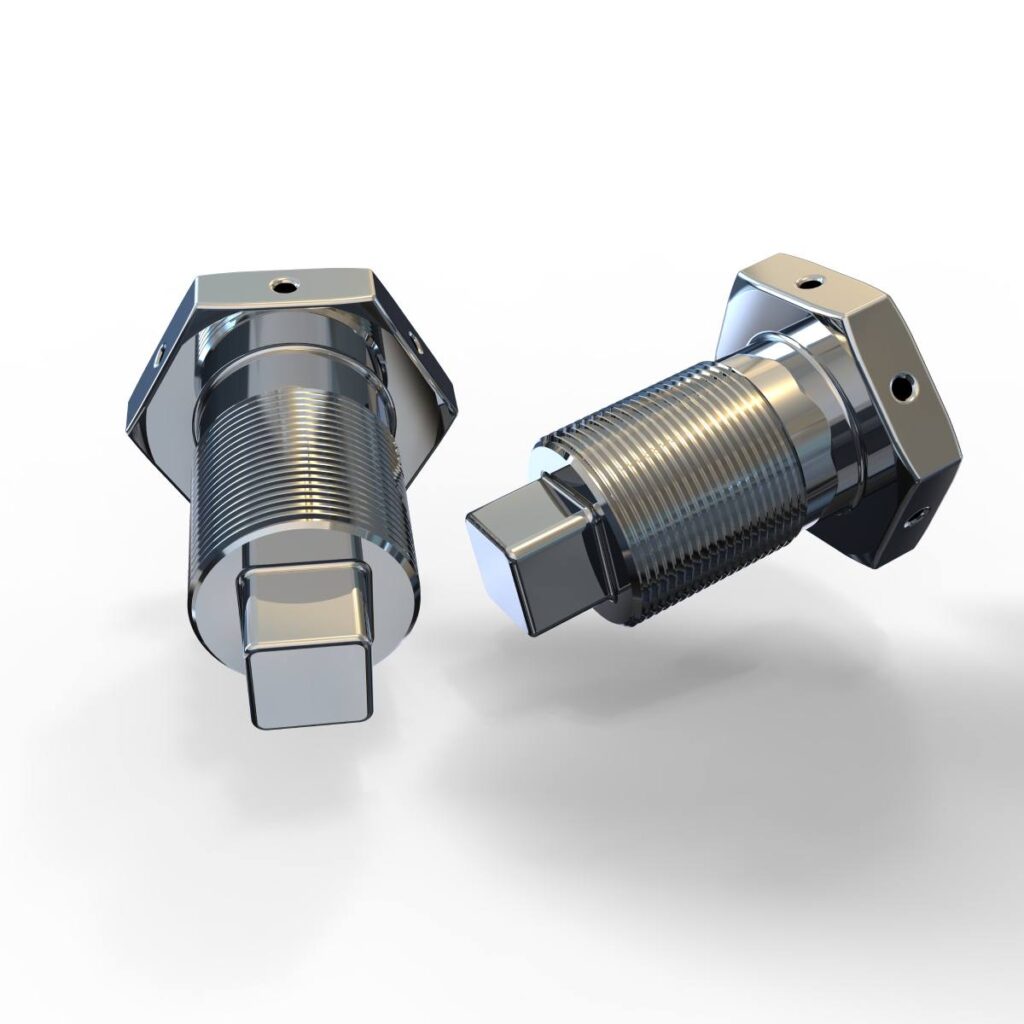

- Mirror polishing

Relying on soft cotton wheels and nano-scale diamond suspensions, a mirror effect of Ra≤0.05 µm is achieved, which meets the ultimate smoothness requirements of optical devices or high-end watch cases.

Applicable scenarios and limitations

- Mechanical polishing: low cost, simple operation, but dependent on manual precision, suitable for simple geometric parts (such as fasteners), difficult to process complex cavities.

- Electrolytic polishing: Uniformly remove the surface layer through electrochemical dissolution, with nanometer precision, suitable for medical implants and aircraft engine blades, but high equipment investment and strict control of electrolyte composition.

- Plasma polishing: Using high-energy ion beams to bombard the surface, complex 3D structures (such as semiconductor molds) can be processed, but a vacuum environment is required, suitable for small batches of high value-added products.

- Chemical polishing: Batch etching with acid (such as HF-HNO3 mixture), high efficiency and low cost, but high environmental pressure, mostly used for uniform matte treatment of bathroom accessories or decorative parts.

Advantages of titanium polishing

The titanium polishing process improves the performance of parts in multiple dimensions by optimizing surface properties.

- Corrosion resistance: Polishing can eliminate surface microcracks and pores and reduce the attachment points of corrosive media. For example, the polished titanium pipes in seawater desalination equipment have a lifespan of more than 3 times longer in a chloride ion environment.

- Wear resistance: Mirror polishing reduces the surface friction coefficient by 40%~60%, which is suitable for automotive piston rings or industrial bearings, significantly reducing the risk of failure caused by wear.

- Conductivity: Polishing removes the oxide layer and exposes the metal body, which increases the conductivity of titanium by 15%~20%, which can optimize energy transmission efficiency when used in electric vehicle battery contacts.

- Biocompatibility: Medical-grade polishing (Ra≤0.05 µm) can inhibit bacterial colonization and reduce the body’s immune response. The polished surface of orthopedic implants can reduce postoperative infection rates by 30%.

Industry applications of polished titanium parts

Aerospace

Polished titanium parts are widely used in aero-engine blades and fuselage structural parts. Mirror polishing reduces surface roughness (Ra value) to less than 0.1 µm, reducing airflow resistance and improving fuel efficiency. For example, the titanium alloy wing spar of the Boeing 787 is electropolished to increase fatigue strength by 20% and reduce weight by 15%.

Medical

Orthopedic implants (such as artificial hip joints) and dental implants rely on medical-grade polishing (Ra≤0.05 µm), whose smooth surface inhibits bacterial growth and promotes bone cell attachment. Johnson & Johnson’s titanium screw polishing process can reduce the risk of postoperative infection by 35%.

Automotive

Polished titanium is used in high-performance exhaust systems, with a high temperature resistance of 600°C and a lifespan that is 50% longer than stainless steel. In electric vehicles, the thermal conductivity of polished battery heat sinks is increased by 18%, which helps with battery thermal management.

Consumer Electronics

The titanium case of the Apple Watch achieves a ceramic-like texture through mirror polishing, while the hardness reaches Mohs 6, and the scratch resistance is far superior to aluminum alloy. Luxury brands such as Cartier also use polished titanium to create light luxury jewelry, which is both light and wear-resistant.

Marine Engineering

After polishing, the titanium alloy pipes in the desalination plant have a chloride ion corrosion resistance life of more than 30 years. The propeller of a Norwegian ship uses polished titanium, and the maintenance cycle in a salt spray environment is extended to 10 years, reducing the operation and maintenance cost by 40%.

Other titanium surface treatment options

Anodizing

Anodizing uses electrolysis to produce an oxide film of controlled thickness on the titanium surface, which supports color customization from dark gray to bright blue (such as the titanium frame of the iPhone) and improves corrosion resistance. The oxide film hardness can reach Mohs 8, which is suitable for building curtain walls or sports equipment. However, the high-voltage process may cause local overheating, and the electrolyte temperature must be precisely controlled.

Electroplating

Electroplating can deposit metal layers such as nickel and gold on the titanium surface, significantly enhancing conductivity (such as 5G base station titanium antenna contacts). The coating thickness can be accurate to the micron level, but the electroplating solution contains cyanide or heavy metals, requiring a wastewater treatment system, and the cost is 30% to 50% higher than polishing.

Wire drawing

Wire drawing uses nylon brushes or sanding belts to create a unidirectional texture to achieve a matte effect (such as high-end kitchenware handles). Although its surface roughness (Ra 0.4–0.8 µm) is higher than polishing, the processing efficiency is increased by 40%, which is suitable for mass-produced furniture or electronic product housings.

Powder coating

Powder coating electrostatically adsorbs epoxy or polyester powder onto the titanium surface, which forms a UV-resistant coating after curing (such as outdoor titanium alloy signage). This technology has no VOC emissions and is RoHS-compliant, but the coating thickness (80–120 µm) may affect the tolerance of precision parts and requires post-processing calibration.

How to choose a titanium polishing service provider

- Equipment accuracy and CNC compatibility

High-precision polishing relies on advanced equipment, especially for complex geometric parts (such as turbine blades or minimally invasive surgical instruments). Priority should be given to service providers equipped with five-axis CNC polishing machines, whose positioning accuracy must be ≤0.005 mm and support customized fixtures to adapt to special-shaped workpieces. For example, medical-grade mirror polishing requires an Ra value of ≤0.05 µm, while automotive structural parts usually require Ra≤0.2 µm. In addition, the introduction of automated optical inspection systems (AOI) can monitor surface defects in real time and increase the yield rate to more than 98%.

- Industry certification and professional qualifications

- Medical field: Service providers must hold ISO 13485 certification to ensure that the implant polishing process complies with aseptic production specifications. For example, the polishing of orthopedic screws must be completed in a Class 10,000 clean room to avoid the risk of biological contamination.

- Aerospace: AS9100 certification is a hard threshold to prove its process traceability and batch consistency. For example, Boeing’s supply chain requires polishers to provide complete material heat treatment and surface roughness reports.

- Environmental certification: RoHS and REACH compliance determine whether a product can enter the EU market, and the service provider’s chemical polishing agent composition and wastewater treatment plan must be verified.

- Environmental compliance and sustainable development

Waste liquid (such as electrolyte) and dust generated by titanium polishing must be strictly controlled. High-quality service providers should be equipped with closed-loop water treatment systems (recovery rate ≥ 90%) and HEPA filtration equipment, and use cyanide-free electroplating or low-VOC polishing agents. For example, a leading manufacturer replaced traditional chemical processes with plasma polishing technology, reducing wastewater emissions by 70% and energy consumption by 40%.

Frequently Asked Questions (FAQs)

Q: How to determine whether titanium parts need polishing?

A: By testing the surface roughness (Ra value), functional requirements (such as corrosion resistance or conductivity) and appearance standards, usually Ra>0.8 µm or parts that need to contact the human body must be polished.

Q: What is the impact of polishing on the dimensional accuracy of titanium parts?

A: Mechanical polishing affects ±0.01–0.03 mm, and electrolytic polishing affects ±0.005–0.01 mm. Precision parts need to reserve polishing allowance in advance.

Q: Comparison of the cost of titanium polishing with other metal polishing?

A: The cost of titanium polishing is about 1.5–2 times that of stainless steel and 60–80% of aluminum alloy, which varies depending on the complexity of the part and the process level.