Subtractive manufacturing is one of the most common and widely used types of precision manufacturing. Specifically, in subtractive manufacturing, as opposed to 3D printing, one starts out with a solid block or structure of material and cuts out with a machine until a desired figure is obtained. This is similarly done by sculptors, although in subtractive manufacturing we replace the sculpting by a machine or robotic arm.

CNC turning and CNC milling are the most common forms of manufacturing in subtractive manufacturing. While in common vernacular they can be used interchangeably, they are in fact different and have their own specific types of strengths, weaknesses and use. In the next lines, we hope to be able to provide the most basic and introductory information on the use of CNC machines to also aid in the step of your upcoming project.

What is CNC Turning?

The process of CNC Turning is where a bar of material is held in a chuck and is made to rotate at a certain speed while a turning tool is fed to and along the desired shape to be made and out of the material. This process is described with different characteristics and is particularly due to the movement described where the workpiece is rotating while the tool is cut. In this specific process, the cutting tool stays in one position while rotating and moving along the other axes.

CNC turning is done on a machine called a lathe or a turning center. since the material is rotating on a spindle, cnc turning is meant for creating cylindrical or tubular parts. If you have to produce a basic shaft, a decorative leg for a table, or a complicated connector for aerospace engineering, turning is mostly the preferred machining method.

The CNC Turning Process

To begin the turning process, a round stock bar is used. This bar is mounted to the spindle on the lathe. The spindle is the main component, as it provides the rotational movement required.

First, the spindle is energized, and the workpiece is rotated at thousands of revolutions per minute (RPM). A turret-mounted tool is brought to the face of the workpiece. The tool, while the spindle is cutting, moves linearly parallel to the cylinder and pulls chips off the workpiece.

As the tool is in cutting contact at all times, the process is quite rapid and very clean cuts can be produced. This is in fact why turning operations CNC turning is usually recognized for its efficiency and high surface finishes.

CNC TURN Operation Types

The term “turning” can be used to describe all operations of a CNC lathe, but depending on the tool and movement pattern of the machine, a few things can be done.

- Facing:This operation is used so the tool can clear the end of the workpiece to create a surface which is perpendicular to the axis of rotation. This surface is usually required so later operations can be done on a part of a known dimension.

- External Turning: The tool moves along the length of the workpiece to reduce its diameter and obtain the main cylindrical shape.

- Boring: to obtain specific internal diameter measurements, a tool moves axially through the workpiece to enlarge a previously drilled hole.

- Threading: This funciton has the machine tool moving and cutting through the exteriors or interiors of the work piece at specific feed rates calculated based on the rotation speed of the spindle cutting the screw threads into the work piece.

- Grooving: This work piece has the machine tool removing a portion of a side of the work piece by cutting it radially that results in a channel or a groove.

- Knurling: A special tool that does not remove material but that presses a surface pattern (usually some diamonds or straight-line designs) into the work piece for the purpose of creating a better grip on the surface of a work piece.

Materials Compatible with CNC Turning

CNC turning can do plenty of different kinds of materials. CNC turning uses a spinning object with a rigid cutting tool. Soft plastics and hardened superalloys can all be handled with CNC turning.

The metals that can be used include: Aluminum (6061, 7075), Brass, Low Carbon Steel, Stainless Steel (303, 304, 316), Titanium, and Magnesium.

The plastics that can be used include: ABS, Nylon, Polycarbonate, PEEK, PTFE (Teflon), and Acrylic.

The material that is chosen is usually can determine the speed cutting and the type of tool that is used. When soft aluminum is used, turning is faster and the tool ends up wearing down less. This is unlike turning heat-treated stainless steel.

Benefits and Drawbacks of Turning

Benefits:

- Speed:For cylindrical parts, turning is significantly faster than milling because the continuous cutting action removes material rapidly.

- Surface Finish:The continuous rotation allows for exceptionally smooth, high-quality finishes without the visible tool marks often left by milling.

- Cost-Effective:For round parts, lathes are generally cheaper to operate and setup than complex mills.

- Accuracy:Excellent for achieving tight tolerances on diameters and concentricity.

Drawbacks:

- Geometric Limitations:You are largely restricted to rotationally symmetrical parts. You cannot easily turn a square box or a complex organic shape that lacks a central axis.

- Tooling Wear:The constant contact can lead to heat buildup, requiring robust cooling strategies and potentially faster tool wear on harder materials.

What is CNC Milling?

When I CNC mill something, I am doing the opposite of turning something. Instead of the workpiece rotating, it is now stationary, and a cutting tool moves across it in a back and forth motion to remove material.

In the manufacting realm, milling machines are the workhorses. They can create any flat surface, and are also able to create slotted pockets, holes, and detailed, three dimensional, zig-zag contours. While turning machine workpieces into a cylinder, milling machine works on creating a cube, and any shape that isn’t just round. Brackets, housings, and any unconventional shape are able to be created.

The number of axes milling machines can move on is also a important piece of categorizind them.

- 3-Axis Milling: On three of the axes, the tool can move in the X, left or right, Y, forward or backward, and Z, up or down, direction. This type of milling is standard for less complex parts.

- 5-Axis Milling: On the 3 axes already described, and 2 more also described in the X and Y directions, the machine has an axis of rotation, or a tilting mechanism either on the cutting tool or on the table of the machine. This configuration allows the cutter to approach the part from almost any direction and is why complex geometries such as turbine blades and complex medical implants are made.

The CNC Milling Process

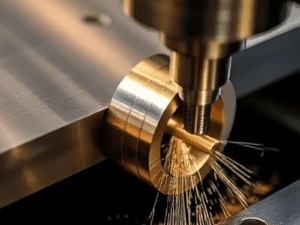

With CNC milling, the process first involves a piece of raw material, referred to a blank, which is secured to the machine’s table with a vice, like in the picture to the right above. In a basic 3-axis milling machine, the material is rigidly held in place, like a lathe.

Next, a cylindrical cutter, which, for all intents and purposes, resembles a drill but can cut to the side, is spun at high speeds in a machine spindle. The CNC computer then directs the spindle to a set of coordinates. While the tool is rotating, it presses down against the material. The tool then shears some material away.

The process is also different in that it is intermittent. The tool is constructed with multiple cutting edges, and each edge of the flute can cut, but it has to exit the part to make room for the spindle to center at the piece. While in a lathe, the process is one continuous cut, which is impossible with this tool.

Types of CNC Milling Operations

As with turning, milling also describes a number of specific operations that can be performed to provide specific features to a part.

- Face Milling: There are large diameter end mills that rotate, on an axis perpendicular to the workpiece surfaces. Primary purpose is to even out the top face of the part to give smooth finish.

- Slab milling: This type of milling has the cutter parallel to the work. This is used for removing large volumes of material quickly.

- Angular milling: The tool makes chamfers, grooves, or dovetails at a certain angle to the workpiece.

- Form milling: Uses a special cutter that is a positive of the desired form ( e.g. a positive curved radius) to cut different shapes in one pass.

- Straddle milling: two or more cutters are mounted on the same arbor, to machine two parallel surfaces simultaneously.

- Gang milling: This is similar to straddle milling, but with multiple cutters that perform several different operations at the same time.

Materials Compatible with CNC Milling

The materials that mills and lathes can use are pretty much the same. Since workpieces are stationary, it’s safer and easier to mill large, unwieldy, or heavy objects that would be too dangerous to spin on a lathe.

- Metals: Steel and its alloys, tool steel, aluminum, brass, copper, titanium, and inconel.

- Plastics: Delrin, nylon, HDPE, UHMW, and PVC.

- Composites: Carbon fiber and fiberglass, though these are abrasive, and would likely need special tools.

Benefits and Drawbacks of Milling

Benefits:

Versatility: The ability to create any shape.

Multi Feature Capability: One setup can do a wide variety of different tasks. Drilling, boring, and tapping.

Scalability: Can make tons of duplicates and easily switch to making something new.

Drawbacks:

Cost: They are expensive to operate and buy, especially 5-axis machines. They are more expensive to program than lathes too.

Waste: Mills often create large amounts of expensive material waste in the form of scrap.

Tool Marks: The cuts can be very noticable, and additional processes may be needed to smooth the surface.

The Key Differences: CNC Turning vs CNC Milling

Both are forms of subtractive CNC manufacturing, but distinctions exist between turning and milling. Knowing these differences can help improve efficiency in your production line.

1.Movement

The main difference is which element of the milling machine is moving.

-Turning means the part rotates and the machine tool stays still.

-Milling means the part stays still and the machine rotates the tool.

This difference alone is enough to alter the output of the shop.

2.Tooling

-Turning employes single-point cutting tools. Keep in mind that only one sharpened tool tip makes contact with the material. This is how smooth and continuous cuts can be made.

-Milling uses multi-point cutting tools. Examples are end mills and face mills, which both have cutting edges along the flute of the tool. This is how non cylindrical stock can be removed in large volumes.

3.Part Shapes

-Turning is only for pieces that have rotation symmetry, which are cylinders, tubes, and spheres. If both of the parts have identical cross-sections that are the same no matter where along the axis of rotation, then it is ready for turning.

-Milling is the opposite. This includes 3D blocks, plates, and other complex asymmetric shapes. If a part has a lot of 2D features such as flat faces and assorted cuts, it probably is one for milling.

4.Chip Formation

-Turning makes continuous, long, and stringy chips. This is a result of constant tool engagement. Often these chips can become wrapped around the tool, an effect that is called ‘bird-nesting’.

-Milling: Produces short, broken chips because of the intermittent cutting action. These are easier to evacuate from the cutting zone.

Choosing the Right Process for Your Project

Choosing CNC Milling or CNC Turning is not always a simple binary decision. Most contemporary machines are “Mill-Turn” centers that incorporate both functionalities. They are able to rotate the part for turning operations while using live toolholders to mill flat surfaces or drill holes on the side.

However, if you have to make a decision on a primary process, you should keep the following factors in mind:

Shape of the Part

Consider the design. Is it circular or round in nature? Is it shaped like a screw, a bolt or a piston? If yes, you should start with turning. If the part is square, rectangular, or asymmetrical shapes like brackets, manifolds, or custom covers, you should start with milling.

Volume of Production

More or less of the same volume, turning is faster and less expensive for high volume of productions that includes cylindrical parts. Swiss Lathe is a type of turning center that does thousands of precise parts in an hour and is very specialized. Milling tends to be slower even if it is for a high volume, it is a necessity for a more complex geometry.

Financial Resources

3, 4, or 5-axis mills in setting up and programming are more expensive than turning centers. If you design your part in a way that it should be turned rather than milled, you are likely to save on production cost.

Conclusion

Having this knowledge about CNC manufacturing gives you the ability to design with more efficiency. You can tailor your parts to the specific machining process that will be used to eliminate unnecessary production, enhance production speed, and reduce costs. Knowing the differences between the rotational precision of a lathe and the general contouring ability of a mill allows you to select the appropriate machining tool for your task.

If you are still not certain which process is ideal for your prototyping, you can stop wondering and take action. Contact our experienced team for guidance on design for manufacturability, or request a quote by submitting your CAD files.

Frequently Asked Questions

Q: Is there mill interpolation turning?

A: Yes, there is a method called interpolation turning, where a mill can imitate a lathe, albeit at a significantly slower pace, and less accurately.

Q: Does CNC turning cost less?

A:Generally, no. For most parts that are suitable (cylindrical) within a given budget, turning is more efficient and less expensive. Milling is preserved for parts that can’t be turned.

Q: What is a mill-turn machine?

A: A hybrid machining center capable of performing turning and milling operations in a single setup. The workpiece rotates for turning, and the machine also has supply rotating tools for drilling or milling features without transferring the workpiece to another machine.

Q: Which process has the best finish?

A: Turning has the better finish on cylindrical parts because the cut is continuous. Milling leaves tool marks where the cutter is in constant rotation.