Galvanized steel is a type of standard steel that has a protective coating of zinc on the surface to prevent the steel from rusting. This article will take you through all the information about galvanizing, its uses, and its benefits, helping you make an informed decision when taking on a CNC machining project.

What Galvanized Steel Is And How It Is Made?

Galvanized steel is manufactured by melding zinc with steel in a manner that protects it from corrosion. Hot dip galvanizing and electro galvanizing are the two most widely used techniques:

Hot Dip Galvanizing

Preparation: An operational cleaning to remove rust or mill scale is done. This is followed by pickling in hydrochloric acid solution and fluxing (applying some form of zinc ammonium chloride for better zinc adhesion).

Immersion: Steel is submerged in molten zinc bath at ~ 450C (842°F), where metallurgical reaction between zinc and steel occurs. This step produces iron-zinc alloys with pure iron on the outer layer.

The result is more than adequate thick enduring coating for zinc to be utilized in fencing and bridges which require significant corrosion resistance.

Electro galvanizing

Process: In this step, steel is dipped into electrolytic bath of zinc in an electrolyte solution containing zinc ions. Applying current leads to electrolysis where in this case zinc is deposited on the surface of steel.

Coating: this procedure results in more refined zinc layer ranging between 3 to 15 microns, which is perfectly adequate for close tolerance parts like CNC machined automotive panels.

Why Use Galvanized Steel in CNC Machining?

Corrosion Resistance for Harsh Environments

Due to its zinc coating, galvanized steel resists moisture, chemicals, and even UV rays. Because of this, it is preferred for CNC machined parts used in the outdoors or in harsh environments like marine equipment, agricultural machinery, or construction hardware. Unlike untreated steel, it avoids costly maintenance due to failing rusted parts. This enhances long-term maintenance significantly.

Cost and Time Efficiency

Galvanized steel fronts corrosion protection at the very start, meaning no additional tasks like paint or powder coating will be required after machining. This alleviates timelines for production and cuts down labor costs for many CNC jobs, especially in high-volume projects.

Durability Without Sacrificing Machinability

Galvanized steel has a hardened exterior. Yet, it’s compatible with CNC tools. When appropriate parameters are set, further enhanced with carbide tooling at moderate speeds, machinists are able to achieve precise cuts while maintaining the integrity of the zinc layer.

Aesthetic and Functional Versatility

Galvanized metals feature a smooth and uniform finish. This boosts their appearance while improving their performance. This is beneficial across many sectors including consumer appliance furniture and automotive sectors where visual appeal and structural integrity are important.

Pros and Cons of Galvanized Steel in Machining

Pros of Used Galvanized Steel

- Outstanding Protection Against Corrosion

Galvanized steel has a zinc coating, which protects the base metal from corrosion due to the elements. This is very beneficial for parts that are prone to rain, saltwater, and industrial chemicals. Outdoor machinery parts and marine hardware, for example, could survive decades without rusting, reducing replacement costs significantly.

- Cost Efficient With Time

While the untreated steel might be cheaper initially, galvanized steel pays off in the long run. Unlike untreated steel, galvanized steel does not require repainting or recoating, making it cheaper in the long term for large scale maintenance works like highway guard rails and warehouse shelving.

- Environmentally Safe Steel

Zinc is galvanizing’s main metal and it is 100 percent recyclable. Unlike other coatings, galvanizing uses modern technology that produces less toxins. For companies that aim for sustainability certifications like LEED, galvanized steel is an optimal choice as it fulfills green manufacturing goals.

Cons of Used Galvanized Steel

- Tool Wear and Increased Difficulty in Machining

The hardened zinc layer is protective, yet abrasive, leading to the premature replacement of CNC cutting tools. To overcome overheating, machinists tend to use carbide-tipped tools, but this makes the workflow more complicated.

- Heat Sensitivity

Galvanized steel should not be subjected to temperatures over 200 degrees Celsius as this can lead to peeling and oxidation of the zinc coating. Hence, it cannot be used for high heat regions like engine components or for use in industrial furnaces.

- Risks of Welding and Damage to Coating

Welding galvanized steel produces toxic zinc fumes, hence requiring specialized ventilation systems. Furthermore, careless handling during machining can also cause a scratch on the coating, leading to weakened spots that are more susceptible to corrosion.

Selecting the Right Kind of Galvanized Steel for CNC Projects

- Begin with Coating Thickness

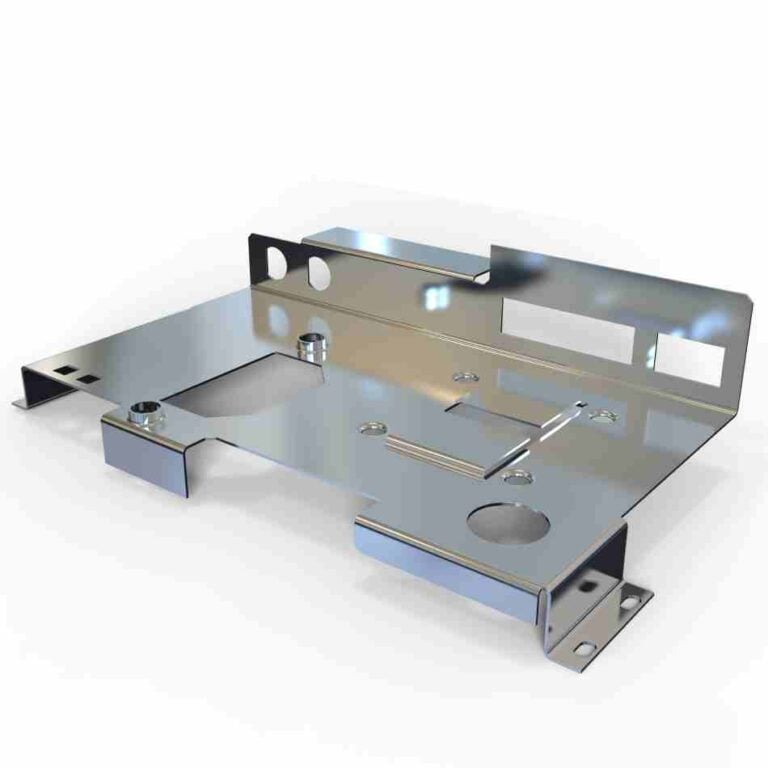

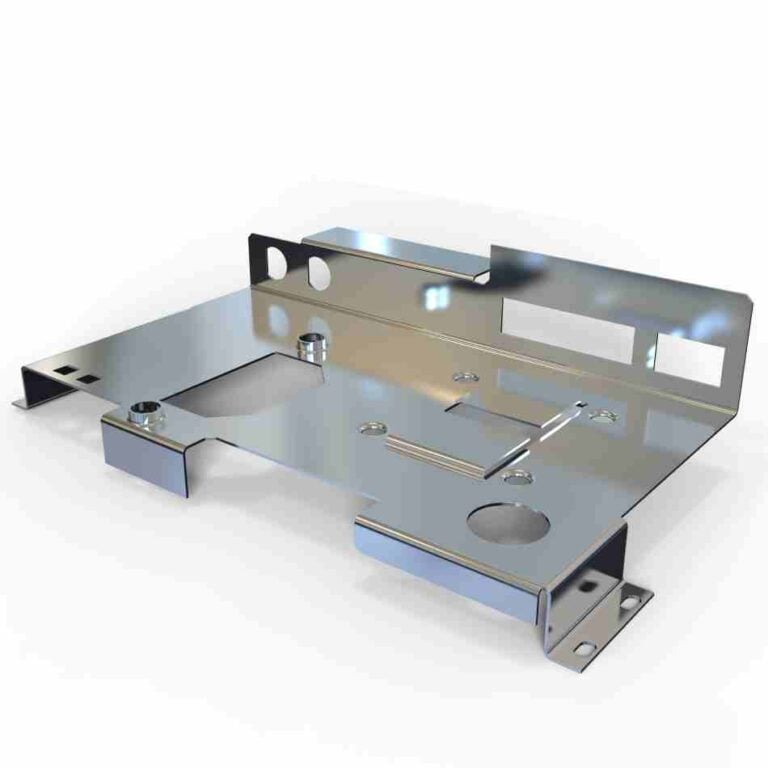

Not all galvanize steels are the same. The thickness of the coating does impact the level of durability. For projects that are kept outdoors like fence posts or agricultural implements, prefer hot dip galvanized steel (G90 coating) with a thickness of 70-100 microns of zinc because it can withstand decades of rain and rust. However, if the project involves machining intricate parts such as electrical enclosures and automotive brackets, thinner layers of electro-galvanized coating that range from 3-15 microns may provide the necessary level of precision while still offering some level of defense.

- Adapt the Quality of the Material to suit your requirement

Galvanized steel has various grades with differing characteristics such as:

ASTM A653 (Commercial Grade) – This is one of the cheapest grades due to all-purpose components that it can be used for like shelving and decorative paneling.

ASTM A123 (Structural Grade) – Higher strength for load bearing components like beams and machinery frames.

Always cross-reference the datasheet to confirm the yield strength as well as the hardness value to avoid any surprises while machining.

- Pay Attention to the Challenges of Machining

The zinc coating can be complex.

If your design involves tight tolerances or deep cuts:

- Utilize Carbide Tools: They’re more effective than high-speed steel at overcoming the abrasive zinc.

- Modify Speeds and Feeds: Decrease spindle speeds (about 20% slower than uncoated steel) to reduce heat buildup and lower the chances of zinc clogging the tools.

- Pro Tip: Test parameters before batch production. A few minutes saved during fine-tuning could prevent expensive tool breaks later.

- Vary Environmental Requirements

High humidity (boats, greenhouses): Use hot-dip coatings.

Indoor use (electronics, furniture): Electro-galvanized steel is good enough and more budget-friendly.

For acidic conditions, galvanized steel may corrode—better to switch to stainless steel.

- Add Aesthetic Touches

Choose smooth, spangled galvanized steel with a glimmering finish if your part is visible. Use cheaper mill-finish grades without looks for hidden components.

- Collaborate with a Reliable Supplier

A dependable supplier can:

- Issue certificates, such as ISO 1461 certification for hot dip galvanizing quality certification.

- Give custom-cut blanks for less time spent machining.

- Suggest costly, time saving options like pre-galvanized versus post-galvanized processing.

Applications of Galvanized Steel in CNC Machining

Construction and Infrastructure

Galvanized steel is commonly used for making bolts which are important in the construction of bridges, scaffolding and buildings due to their CNC machined parts like brackets, fasteners and beams. It offers protection from severe weather thus enhancing the structural integrity of the outdoor structures.

Automotive Parts

CNC Machining is required in agriculture industry’s plowing, harvesting and irrigation equipment as they function in swampy areas. Galvanized steel is used in generating parts such as chassis, brackets and exhaust systems.

Outdoor Furniture and Fixtures

Galvanized steel increases the life span of agricultural machines like gears and frames as they do not suffer from rust. Gardening benches and light poles benefit greatly from galvanized steel since they provide a lot of strength combined with good-looking design.

Electrical Enclosures and Cabinets

Galvanized steel serves the purpose of protecting sensitive electrical components from moisture, rot and rust when used in electrical enclosures and control cabinets.

Renewable Energy Systems

The use of galvanized steel in solar and wind energy systems is for mounting structures and support frames.

Conclusion

Ready for your next project? With CNC projects that require severe impact resistance that also need to be cost effective, choosing galvanized steel serves as an optimal selection. By picking the correct grade and optimizing machining practices, its advantages can be utilized while challenges like tool wear are dealt with.

Frequently Asked Questions (FAQ)

Q: Stainless Steel is Stronger Than Galvanized Steel, Correct?

A: No, stainless steel does have a higher strength, but galvanized steel is cheaper in terms of corrosion environments.

Q: Is Welding Galvanized Steel Possible?

A: Yes, proper ventilation is essential to avoid the inhalation of noxious zinc fumes.

Q: What Maintenance Does Galvanized Steel Require?

A: Regular cleaning with mild soap and water will reduce dirt build-up. Use non-abrasive implements, and touch up any minor scuffs with zinc-rich paint to sustain the corrosion resistance.

Q: How Does Galvanized Steel Differ From Stainless Steel?

A: Galvanized steel is the more cost-effective option as it is carbon steel with a zinc coating offering resistance to rust, while stainless steel contains stronger corrosion resistant materials such as chromium which increases strength but at a cost.

Q: Is It Possible To Paint Galvanized Steel?

A: Yes, if the surface is prepped by washing it and applying a primer suited for galvanized metals, paint can be applied. The proper preparation will guarantee adhesion and longevity of paint.