When you need to make a perfectly flat surface on a piece of metal, plain milling is your go-to move. Think of it as the machining world’s equivalent of using a giant, incredibly precise planer. But getting it right isn’t just about pushing a button. The real magic happens when you know how to pick the best tools, understand which materials work well together, and keep your equipment in top shape with smart maintenance.

This guide is here to break down all of that for you. We’ll walk through everything you need to know to master this essential process, avoid common headaches, and get awesome results every time.

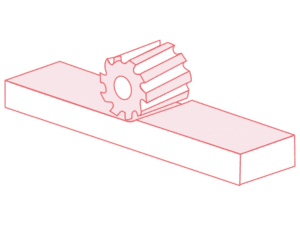

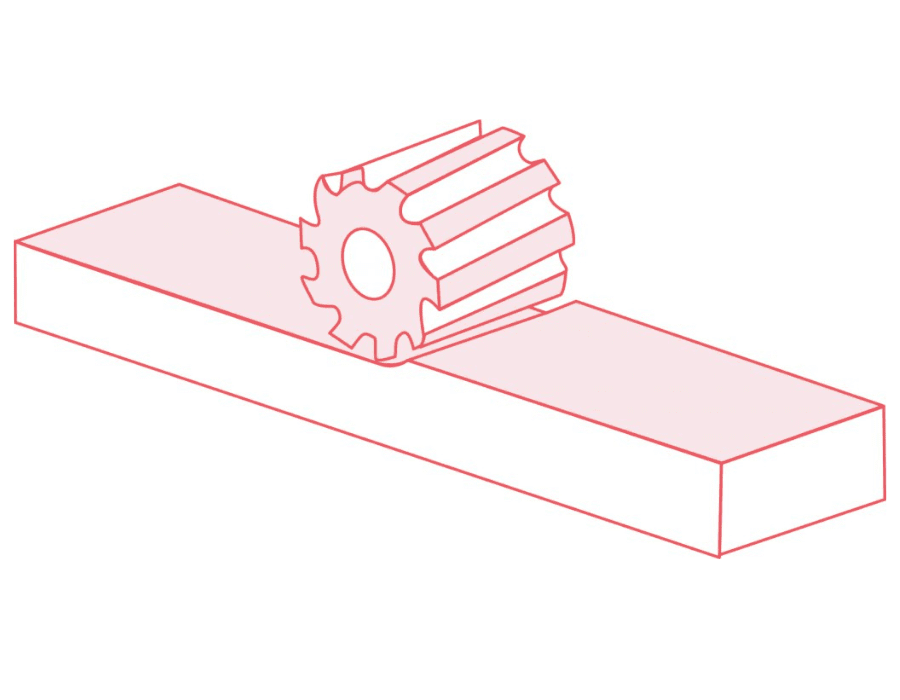

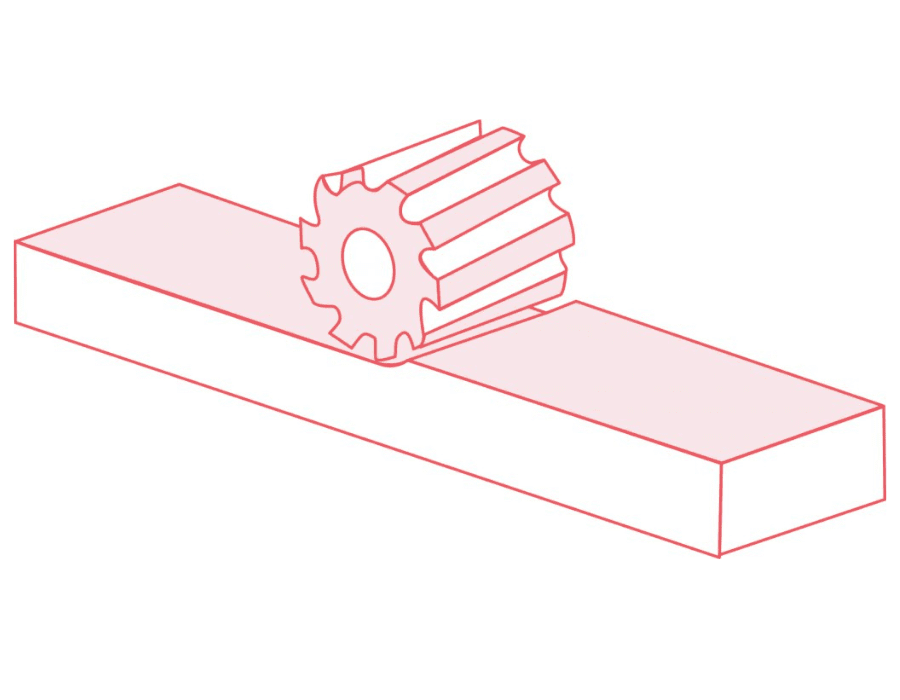

What is Plain Milling?

Simply put, plain milling is the fundamental machining process for creating flat, horizontal surfaces. Also known as slab milling or surface milling, it uses a rotating cutter’s periphery to remove material. Its key feature is that the cutting action happens on the teeth located on the cutter’s circumference, unlike face milling which uses the tool’s end face. Think of it as using the side of the tool to skim away layers, perfect for producing large, smooth planes on a workpiece.

Equipment and Tool Selection Guide

Milling Machine Types and Selection

Horizontal vs. Vertical Milling Machines

- Horizontal Mills are the classic choice for plain milling. Their design provides superior rigidity and power for heavy-duty material removal across large surfaces, making them ideal for slab milling operations.

- Vertical Mills are highly versatile and common. They can perform plain milling using a face mill or shell mill, but may be less optimal for the very widest cuts compared to horizontal setups.

- Universal Mills feature a table that can be swiveled, enabling multi-axis machining for complex angles and helical milling operations, adding significant flexibility.

CNC vs. Manual Machine Considerations

- Automation & Precision: CNC machines offer unmatched automation, repeatability, and precision for high-volume production runs.

- Cost & Skill: Manual mills have a lower upfront cost and are excellent for prototypes but demand more operator skill and are slower for batch production.

- Selection Criteria: The choice ultimately depends on production volume, required precision, workpiece size, and available budget and operator expertise.

Plain Milling Cutter Types and Selection

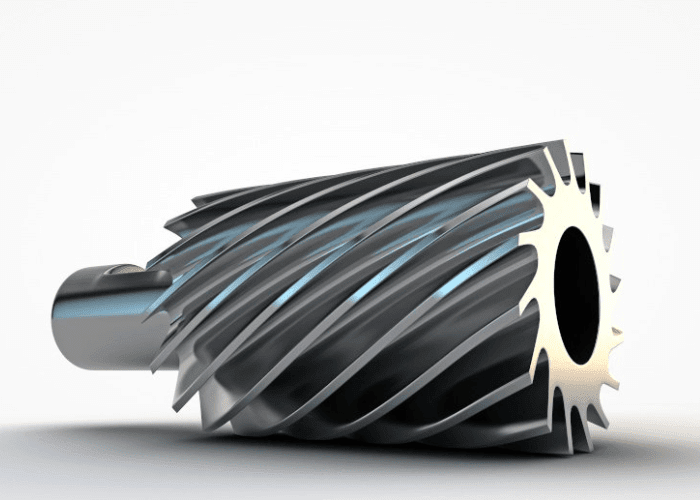

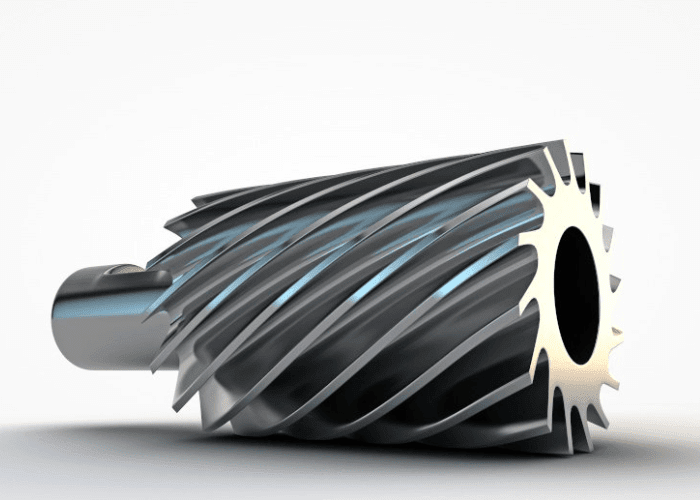

Heavy-Duty Plain Milling Cutters

Characteristics: Feature a high helix angle (25-45°), fewer teeth, and large chip gullets for efficient chip evacuation.

Applications: Primarily designed for aggressive roughing operations and high material removal rates (MRR) on tough materials like structural steel and cast iron.

Performance: Can typically handle depths of cut of 8mm or more per pass.

Light-Duty Plain Milling Cutters

Characteristics: Have a lower helix angle, more teeth (14-20 flutes), and a finer pitch.

Applications: Used for finishing operations on softer materials like aluminum, plastics, and composites to achieve a superior surface finish.

Performance: Optimized for finer cuts (2-3mm) and achieving surface finishes of Ra 1.6 micrometers or better.

Specialized Cutters

Slab Mills: Very wide, single-purpose cutters for machining large surfaces in a single pass.

Fly Cutters: A simple, cost-effective tool with a single cutting bit, excellent for achieving a fine finish on large aluminum surfaces.

Coated Cutters: Tools with TiN or TiAlN coatings offer significantly extended tool life and higher heat resistance during plain milling.

Cutter Material Selection Guide

Material Types and Properties

- High-Speed Steel (HSS): A durable and cost-effective option with good toughness, suitable for intermittent cuts and general-purpose use on various materials.

- Carbide: The industry standard for most plain milling applications. Offers superior hardness, heat resistance (up to 1000°C), and allows for much higher cutting speeds than HSS.

- Cermet: Excellent for finishing and semi-finishing applications, providing a very good surface finish and wear resistance.

- Ceramic: Used for high-speed machining of hard-to-cut materials like super alloys due to its extreme heat resistance.

- Coatings: TiAlN is a common, high-performance coating that reduces friction and thermal load, drastically increasing tool life across all material types.

Selection Criteria

The primary rule is to match the cutter material to the workpiece material.

Use high-speed steel for small-batch jobs and softer materials, and upgrade to carbide for higher production volumes and harder materials.

Consider coated tools for abrasive materials or to maximize tool life and minimize downtime in continuous operations.

Material Categories and Machinability

Successful plain milling hinges on understanding your material’s properties. Its machinability—how easily it can be cut—directly dictates your tool selection, speeds, feeds, and overall strategy.

Metals and Alloys

Aluminum Alloys: Materials like 6061 or 7075 are highly machinable. Use sharp, polished carbide cutters with a high helix angle for efficient chip evacuation. High spindle speeds and feed rates are optimal to prevent material buildup on the tool.

Carbon & Alloy Steels: These require robust tooling and careful heat management. Using carbide inserts with wear-resistant coatings like TiAlN is advised. Employ ample coolant to manage temperature and maintain tool hardness.

Stainless Steel: Prone to work hardening, which can quickly damage tools. It’s crucial to maintain a consistent feed rate and use a sharp cutter with a positive rake angle to minimize heat and pressure that cause hardening.

Cast Iron: Typically machined dry. The abrasive graphite flakes require a hard, abrasion-resistant tool material like carbide or cermet. Focus on chip control and use a cutter designed to break up the dusty, abrasive chips.

Titanium & Superalloys (e.g., Inconel): Present the greatest challenge due to their strength at high temperatures. They require sharp carbide tools, slow surface speeds, high feed rates, and high-pressure coolant to manage heat and prevent work hardening.

Non-Metallic Materials

Engineering Plastics (PVC, Nylon): These materials are soft but require sharp, high-positive rake tools to achieve a clean cut without melting. Heat generation is the primary concern. Use high speeds with low feed rates and compressed air for cooling to prevent the material from deforming.

Composite Materials (e.g., Carbon Fiber): Extremely abrasive and require specialized tools, often diamond-coated carbide, to withstand wear. Dust control is critical for operator safety. The goal is a clean cut to prevent delamination and fraying of the fibers.

Material Selection Guide for Plain Milling Projects

Here’s a concise guide to key selection factors

- Cost-Effectiveness: Consider the total project cost, not just the raw material price. Easily machined materials like aluminum may have a higher initial cost but much lower machining time, often making them more economical overall for complex parts compared to cheaper but tougher-to-machine steels.

- Machinability Ratings & Productivity: This rating directly impacts your throughput. Materials with high machinability (e.g., 1212 Steel, Aluminum 6061) allow for higher feed rates and speeds, drastically boosting productivity. Low machinability materials (e.g., stainless steel, titanium) require slower parameters, increasing cycle times and cost.

- Surface Finish Achievability: If your application requires a fine finish, material choice is crucial. Aluminum and brass can achieve excellent surface quality relatively easily. Conversely, cast iron and abrasive composites can be challenging, often requiring secondary operations to meet strict finish requirements.

- Tool Life Expectancy: Abrasive or hard materials dramatically reduce tool life. Machining carbon fiber or stainless steel will consume carbide cutters far faster than machining mild steel or plastics, increasing tooling costs and downtime for changes.

Applications of Plain Milling

Aerospace

Plain milling is essential for machining large airframe structures like wing panels and fuselage sections from aluminum alloys. For engine components such as mounting brackets, the process meets extreme precision requirements and tight tolerances for weight reduction. Machining material challenges like titanium demands specialized tooling and techniques, as seen in Boeing 787 component manufacturing, where surface integrity is critical.

Automotive

In automotive manufacturing, plain milling machines engine components like cylinder blocks and heads, as well as transmission parts such as housing surfaces. The process fulfills mass production requirements with high-volume efficiency while adhering to stringent quality standards. A case study on Ford EcoBoost engine manufacturing highlights how optimized tool paths ensure durability and precision.

Medical Device Manufacturing

Plain milling produces implant production components like bone plates and surgical instruments with exceptional accuracy. The process meets biocompatibility requirements by achieving flawless surfaces free of contaminants. It adheres to strict precision standards for medical-grade tolerances, as demonstrated in orthopedic implant surface preparation for joint replacements.

Electronics and Telecommunications

This sector uses plain milling for heat sink manufacturing to create thermal management components with optimal flatness. The process machines housing and enclosures for devices, meeting precision requirements like tight dimensional controls. It also achieves surface finish standards that are both aesthetically pleasing and functional for EMI shielding.

Construction and Heavy Equipment

Plain milling machines large structural components and equipment brackets for bulldozers and cranes. The process addresses scale considerations through rigid setups and powerful machinery. It ensures durability requirements by achieving precise flatness for load-bearing surfaces in harsh environments.

Conclusion

Ready to elevate your manufacturing project? Our expert CNC plain milling services combine precision tool selection, material expertise, and rigorous quality control to deliver flawless results. Trust our advanced capabilities for your most demanding components—contact us today for a customized machining solution.

Frequently Asked Questions (FAQ)

Q: What distinguishes plain milling from face milling?

A: Plain milling uses the cutter’s periphery to create horizontal surfaces, while face milling uses the tool’s end face. They are distinct processes for different surface orientations.

Q: Is slab milling the same as plain milling?

A: Yes, slab milling is simply another name for plain milling. Both terms refer to the same fundamental process of machining large, flat surfaces.

Q: What materials can be plain milled?

A: Virtually all machinable materials can be processed, from aluminum and steel to plastics and composites. The key is using the correct cutter and parameters for each material’s properties.